The Challenge

Revitalize the Custom Footwear Business

New Balance, like most other athletic companies, offering custom footwear online. Consumers pick the materials and colors they want on specific styles to make the shoes one of a kind. New Balance set themselves apart from competitors by featuring styles that were made in their US factories for “Made in America” appeal. This meant that the styles offered for customization were more of a lifestyle appeal than the athletic focused styles offered by competitors.

But after a successful launch, the business was left alone, in favor of higher priorities. The quick fix approach of adding new featured materials seasonally to refresh the offerings led to more problems. Vendors were unhappy with New Balance for the frequent requests for small quantities of special materials. The factories were having to manage a vast quantity of material changes for every custom order they made. And sales were still declining. A team was assembled to focus on customization and turn around the profitability of the business.

The Approach

Front and back stage experiences

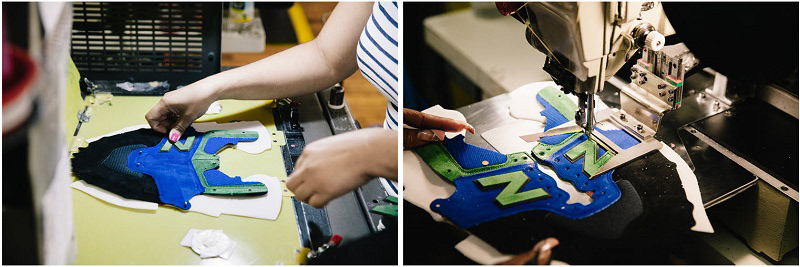

To understand the logistical challenges experienced by our factory and vendors I ran a co-design workshop with stakeholders to map out the journey our materials take from vendor to finished shoe and understand the biggest challenges customization adds to their typical workflow.

To understand the customer need, contextual interviews were conducted after observing customers design their own custom shoes. Resonance testing of new ideas were also conducted with some of the same customers. A cultural probe was also used with customers, who provided images about their home environment, including closets, and selfies that reflected their personal style.

Customer designing shoe with in-store touch screen (old customizer)

Custom Line in US factory must switch thread colors dozens of times a day

Highlights of Research

Analysis paralysis leads to fear of purchase or sometimes trouble even starting A blank page is daunting to even seasoned creative professionals. Even those most excited about the opportunity to create their own shoes were overwhelmed by a blank (all white) shoe. Consumers didn’t approach a shoe from the color blocking perspective that a designer would, typically they started with the toe or tip as these are the parts that they see the most when looking down while wearing them.

American manufacturing sets different expectations for custom product Despite the steady decline of American based manufacturing across all industries, consumers still view Made in America as synonymous with quality. As excited as buyers are to see their creation, 2-day delivery was not a major factor. Consumers expected to see perfection for their hand crafted creation and would scrutinize loose threads or glue over-runs in a way they didn’t for custom products coming from Asia.

Analysis

Personas

(above), created following contextual interviews, helped refocus the messaging to customers. It became clear that the custom consumer was driven not by NB brand loyalty but by the novelty of custom. Those inclined to customize their own products quickly grew bored with the color/ material palette that only contained basics and never seemed to change- an approach that was tried and true for our traditional in-line customers. We refocused the business to build on the desires of these trend setting consumers through refreshing the material and color options seasonally with overstock from in-line releases. This allows us to not only to reduce the burden on our vendors and factory, but also capitalize on the marketing campaigns for regular releases, and provide our NB1 customers with fresh, on-trend stories that they can make their own and share with their followers.

Journey Map

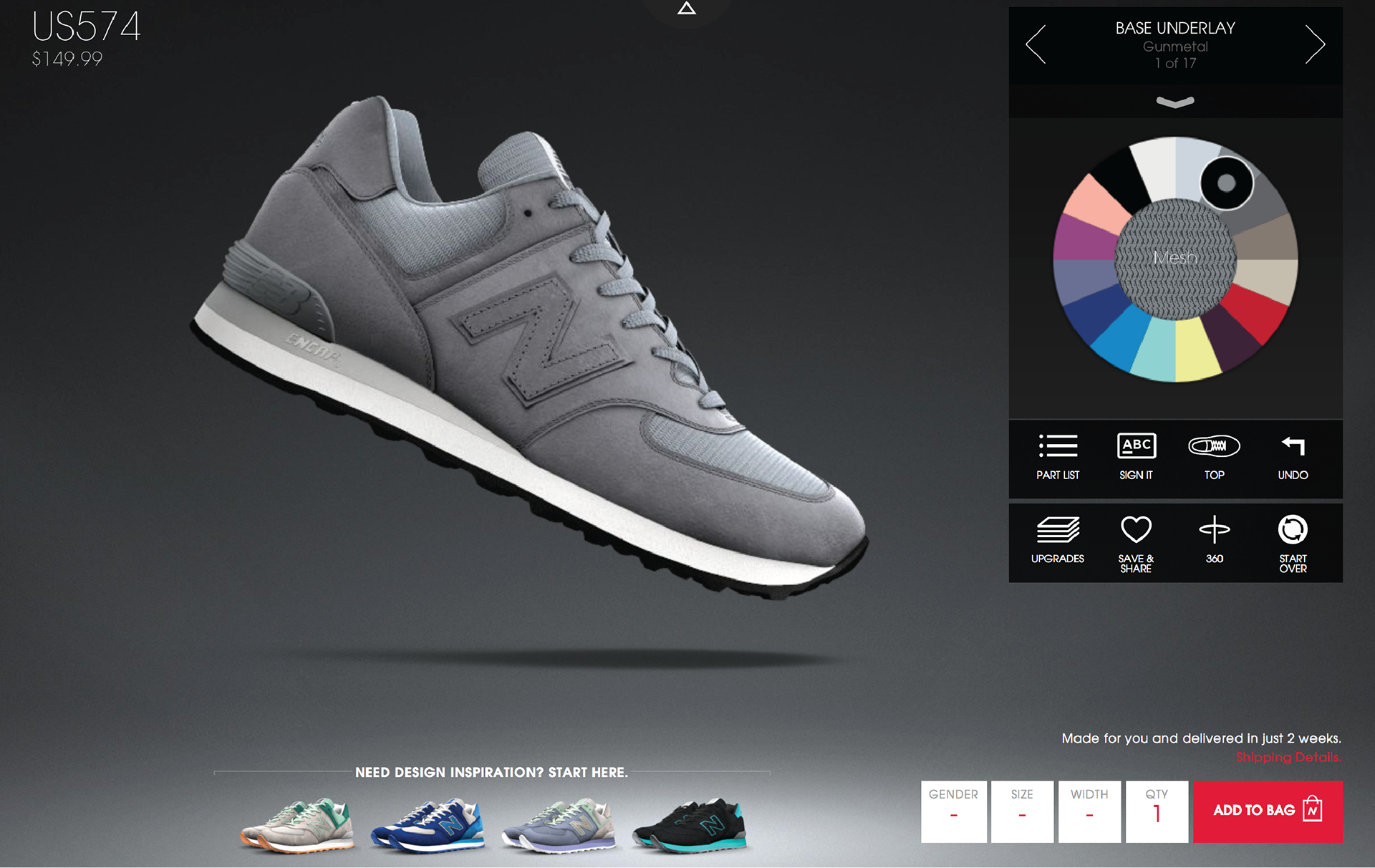

(below) helped identify touch points throughout the purchase process that could improve the customer experience as well as impact our factory and vendor experience. For example, one of the biggest drop off points for customers was follow through on purchase after they have added their creation to their cart. An improved UX of the custom website with new features like pre-built "starter templates" and user-friendly steps to pick their colors and materials drastically improved cart abandonment and also decreased return requests due to unfulfilled expectations.

Impact

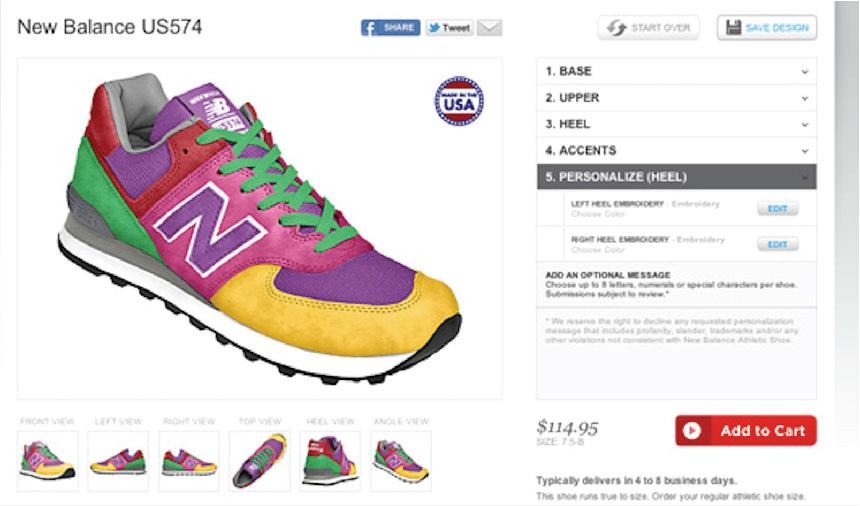

The redesigned website focused on user experience throughout the customization process. The selection of parts was reordered and renamed to address the way consumers think about picking colors. Color options were arranged in a color wheel to better set expectations. Inspirational shoe designs were added to be used as a starting point for consumers with creative block. This and other UX adjustments resulted in noticeable improvements to the business, such as:

Sales increase

36% decrease in return requests for custom purchases

10% decrease in cart abandonment rate

Old Customizer UX

New Customizer UX

Behind the scenes, a reduced color/material palette and introduction of specialized materials resulted in decreased burden on our factory and vendors. By using specialized materials already purchased for featured lifestyle launches including:

Renewed relationship with vendors

Reduced inventory and overstock

Reduced change over of colors on factory line

Horween Leather launched with in-line Horween 997s

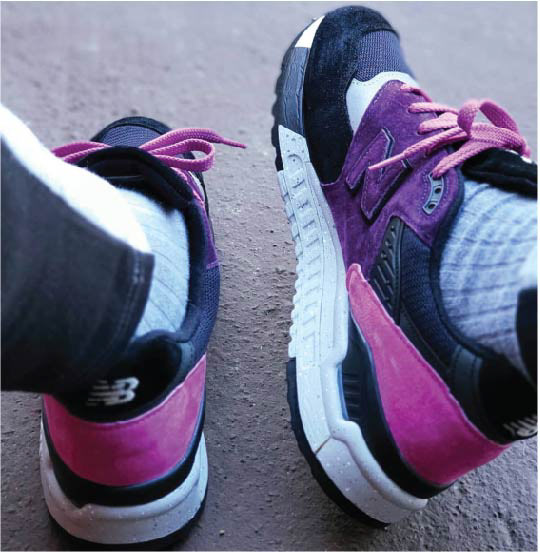

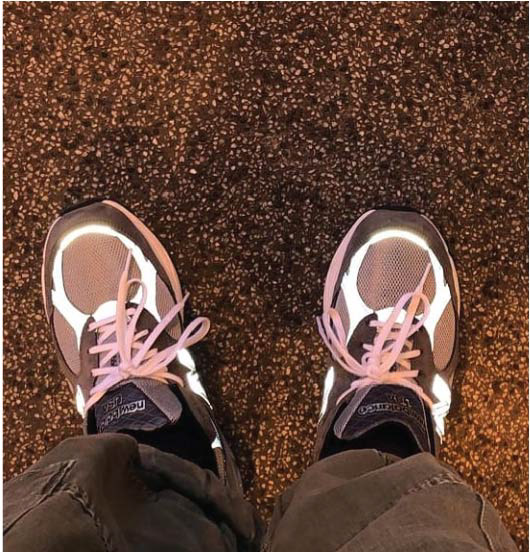

Influencer launch of new style

Influencer launch of new style

Denim overstock from in-line release as custom material to "make yours"